Powering EVs, From A to Z

End-to-end, fully integrated solutions for autonomous and electric vehicles

Comprehensive EV Battery Solutions

EV Battery Products

- Products

- Battery Cells

- Thermal Management

- Battery Housing

- Hydrogen Vessels

- E & E

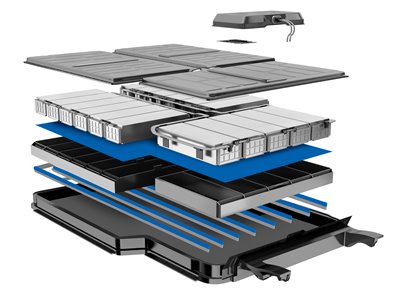

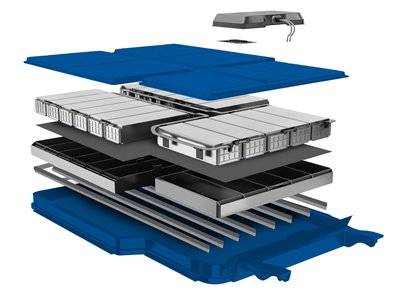

EV Battery Housing Technology

Mitsubishi Chemical Group offers numerous battery pack housing and enclosure solutions.

FR CF-FMC | Forged Molding Compound

Carbon Fiber Forged Molding Compound (CF-FMC™) is created from chopped carbon fiber and resin and delievers strength comparable to aluminum alloys while offering short molding cycles with excellent moldability and design flexibility.

CF-FMC™ benefits include short cycle time -- which makes it ideal for volume automated production, design of complex geometries, and less CO2 emissions.

- Carbon fiber 53% by weight

- Vinyl ester resin base

- Flame retardant, non-halogenated

- Excellent mechanical property and moldability with UL94 V0 @ 3mm thickness

GMT eFR | Fiber Reinforced Thermoplastics

Mitsubishi Chemical Group has developed a flame-retardant battery protection material to address flammability concerns with EV batteries. GMT eFR has the same mechanical stiffness, impact, and crash properties as GMT, but now conforms to GB/T 38031-2020.

GMT eFR benefits include its low relative density, excellent rigidity even at low temperatures, chemical and moisture resistance, and ease of recycling.

-

Lightweight, halogen-free material

-

Flexibility of design range with parts integration

-

Streamlined assembly process for high productivity

-

Positive end-of-life with recyclable materials

FR PrePreg | Compression Molding

Our prepreg compression molded material is suitable for producing an EV battery housing unit that requires flame retardancy and high mechanical properties.

Prepreg compression molded material benefits include short cycle times, superior dynamics, and the possibility for individualization and unique geometry.

- 33% weight savings over aluminum

- Lower center of gravity

- Process automatization for volume production

- Less investment costs for tooling compared to metal solutions

Collaboration & Partnerships

We provide ourselves as a company that offers innovative solutions for our customers through product and application development.

From reimagining lightweight structural applications that reduce fuel consumption to redesigning parts to reduce components and processes, our customer-centric approach ensures mutual success. With a focus on decreasing the environmental impact, we partner with customers to develop solutions to their most challenging problems.

Our Performance Polymer Division's partnership with STANT CORPORATION is one of many partnership successes in driving application success, demonstrating how a plastic fuel filler pipe can be produced with a 3-layer construction via the SBM (suction-blow-molding) process.

Product Used:

- ADTEX™/MODIC™ | Are resins of polyolefin compounds grafted with maleic anhydride.

Main Function: To provide adhesion and compatibility between different materials.

Benefits:

- Excellent bond strength with various resins

- Contributes to evaporative emissions performance.

Contact us today to learn more about how we can help.

"In 2020 Stant and MCA (Mitsubishi Chemical Americas) successfully completed a joint development project demonstrating a plastic filler fuel filler pipe can be produced with a 3-layer construction via the SBM (suction-blow-molding) process.

Permeation test results were excellent and better than expected. Although this material combination was not taken to production, it should be considered ready for product design verification testing.”

~Darl Dufendach

Stant Corporation

Research & Development

Thermal Interface

Materials for EV

Composites for EV

Battery Protection

Product Spotlight: Thermal Interface Materials for EV

Advances in electric and hybrid vehicle designs have led to the densification of electrical components and increased power output. To maintain electronic device performance and longevity, the protective materials used in these devices must also push the limits of performance and be adaptable to new and smaller designs. Gelest specializes in custom-developing thermally conductive silicones for potting and encapsulating, gap filler, and adhesive applications.

Product Spotlight: EV Battery Protection

Our Advanced Materials division is working on ways to combine thermal runaway protection and electromagnetic interference (EMI.) Our thermoplastic and thermoset technology is an ideal solution to improve manufacturing techniques to protect against extreme runaway temperatures and external electromagnetic signal interference to improve material added value while decreasing manufacturing processing steps to improve ROI.

Global Reach

69,784

Employees

(consolidated)

0

Subsidiaries & Affiliates

$0B

Sales Revenue

(consolidated FY2021)